PROTECTO 401’™S ABILITY TO PROTECT DUCTILE IRON FROM ACID ATTACK

Induron has included independent test data concerning the growth of Acidithiobacillus Bacteria on the Protecto 401 Ceramic Epoxy lining of ductile iron pipe and fittings. The growth of this bacteria contributes to the erosion of ferrous metals and concrete in sewer service, since this bacteria produces sulfuric acid as a waste product when it consumes hydrogen sulfide.

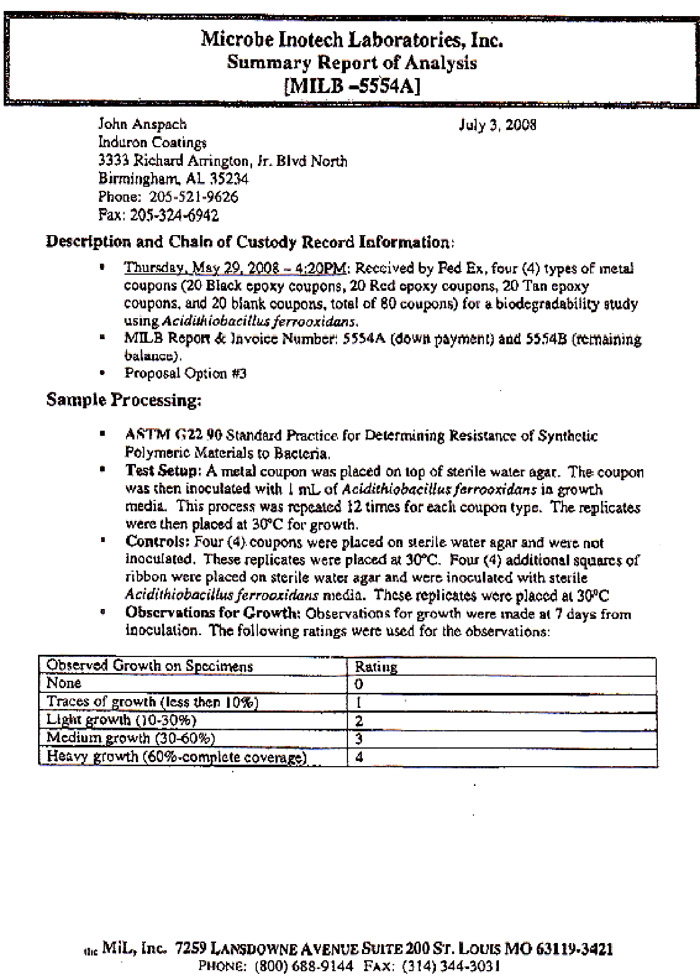

It is our opinion, based upon ASTM G 22 90 Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Bacteria, that Protecto 401 Ceramic Epoxy is not only an excellent barrier coat with zero permeability and resistance to high percentages of both bases and acids but also a non-ablative (non-sacrificing) bactericide which dramatically reduces the growth of thiobacillus bacteria, the main culprit in damage to sewer lines.

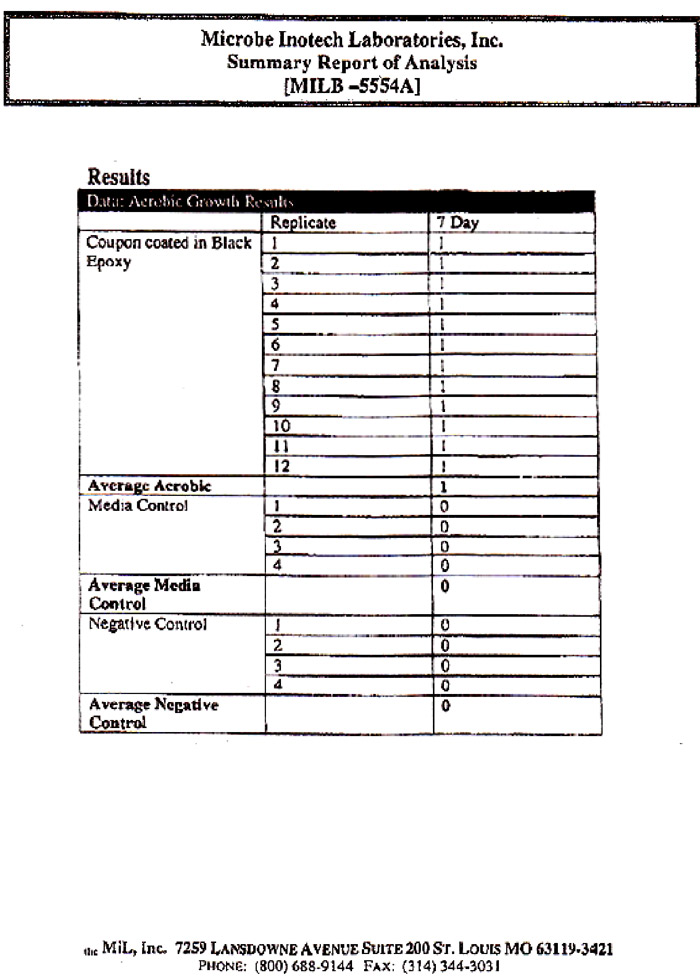

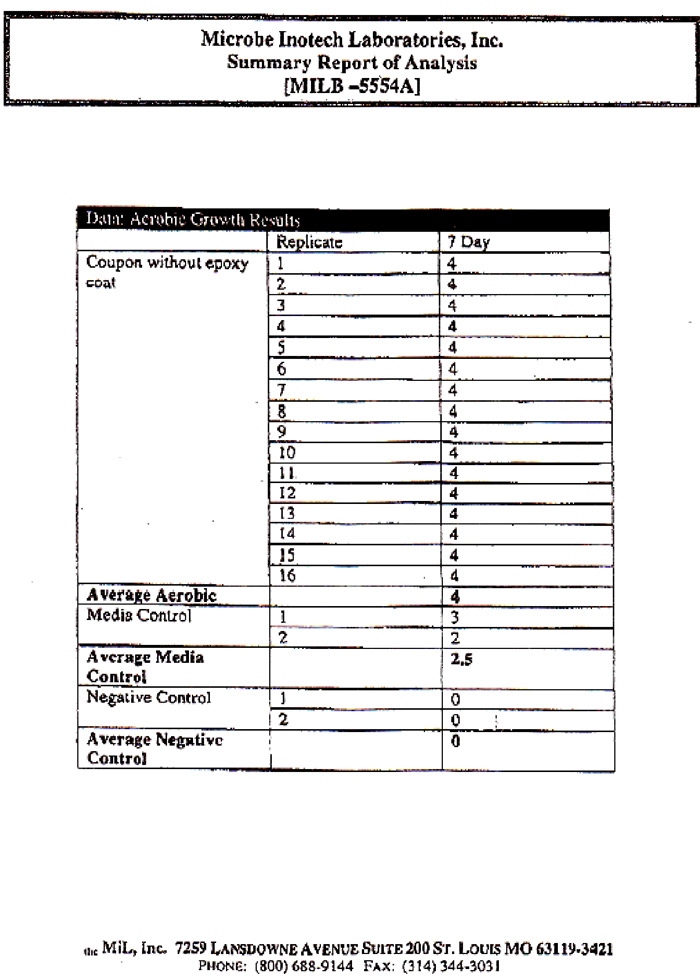

Because Protecto 401 Ceramic Epoxy is constructed to produce a lining that has a higher ph throughout the lining – and acidithiobacillus have to have an acid environment to flourish – then Protecto 401 Ceramic Epoxy acts as a bactericide without any loss of film integrity. The proof is in the testing. (see attached) The bare metal grows acidithiobacillus, when subjected to the warm moist climate and inoculated with the bacteria, at an alarming rate. Protecto 401 Ceramic Epoxy , which is referred to as the Black Epoxy Coupons in the test data, limits growth to only traces.

This added advantage plus the unique construction of Protecto 401 Ceramic Epoxy is the reason for the longevity of Protecto 401 Ceramic Epoxy in sewer service on ductile iron pipe and fittings.