|

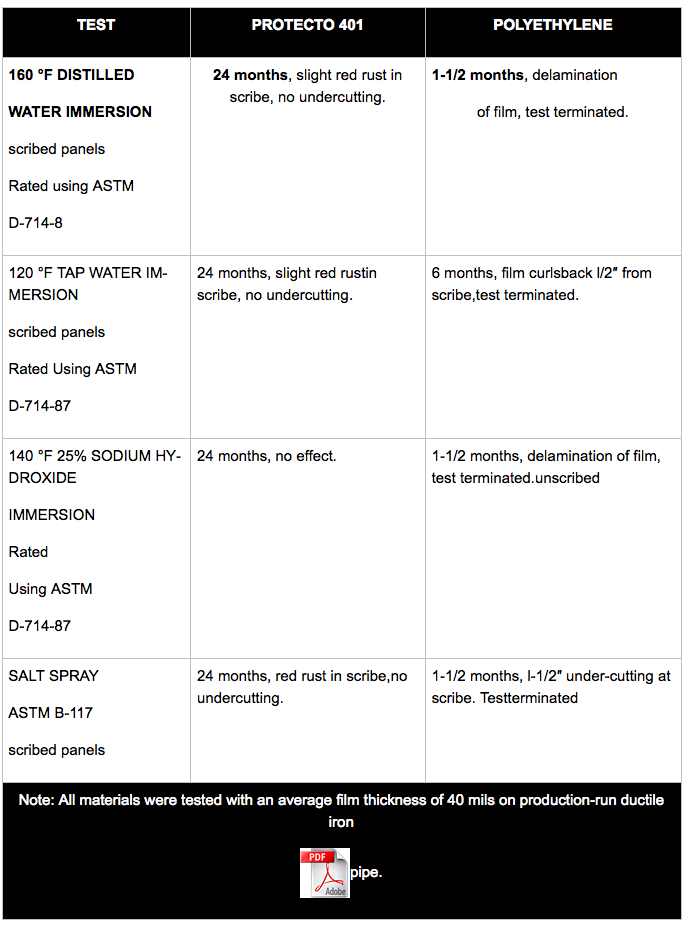

TEST |

PROTECTO 401 |

POLYETHYLENE |

|

160 °F DISTILLED WATER IMMERSION scribed panels Rated using ASTM D-714-8 |

24 months, slight red rust in scribe, no undercutting. |

1-1/2 months, delamination of film, test terminated. |

|

120 °F TAP WATER IMMERSION scribed panels Rated Using ASTM D-714-87 |

24 months, slight red rustin scribe, no undercutting. |

6 months, film curlsback l/2″ from scribe,test terminated. |

|

140 °F 25% SODIUM HYDROXIDE IMMERSION Rated Using ASTM D-714-87 |

24 months, no effect. |

1-1/2 months, delamination of film, test terminated.unscribed |

|

SALT SPRAY ASTM B-117 scribed panels |

24 months, red rust in scribe,no undercutting. |

1-1/2 months, l-1/2″ under-cutting at scribe. Testterminated |

|

Note: All materials were tested with an average film thickness of 40 mils on production-run ductile iron |

||

PROTECTO 401 VS. POLYETHYLENE