COATING DATA |

DESCRIPTION:

A two-component, high solids, chemically cured epoxy coating. Ceramapure PL90 Ceramic Epoxy is a unique barrier coating formulated for the protection of ductile iron pipe and fittings for water or sewer service.

Ceramapure PL90 is certified for cold end uses only to NSF/ANSI International Standard 61 for potable water immersion service for pipe diameters of four inches or larger.Ceramapure PL90 meets or exceeds the compliance standards for AWWA C-210.

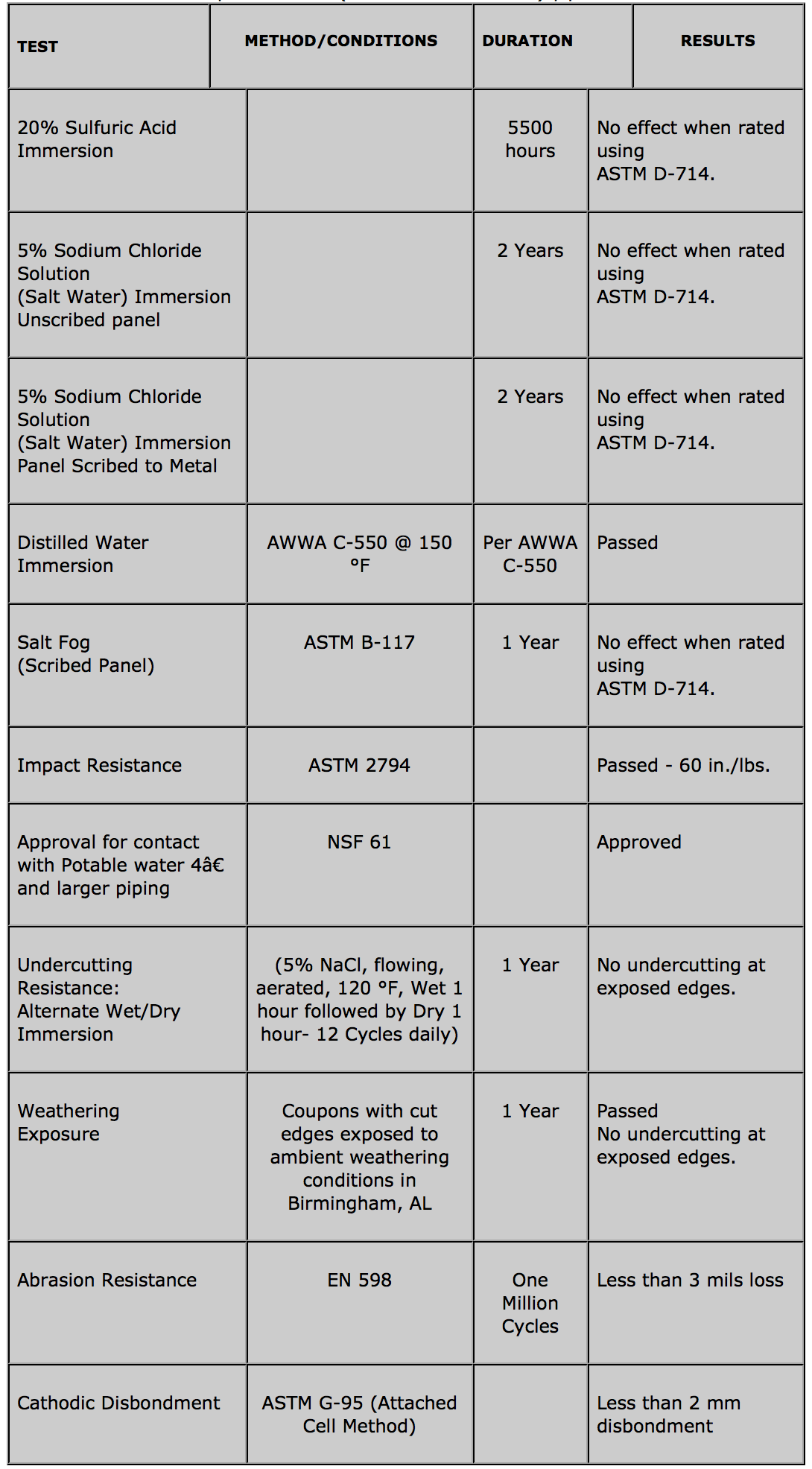

PERFORMANCE TESTING

PANEL: Ductile Iron Pipe SYSTEM: Ceramapure PL 90

Cathodic Disbondment | ASTM G-95 (Attached Cell Method) | | Less than 2 mm disbondment

TEST |

METHOD/CONDITIONS |

DURATION |

RESULTS |

||

| 20% Sulfuric Acid Immersion |

5500 hours |

No effect when rated using ASTM D-714. |

|||

| 5% Sodium Chloride Solution (Salt Water) Immersion Unscribed panel |

2 Years |

No effect when rated using ASTM D-714. |

|||

| 5% Sodium Chloride Solution (Salt Water) Immersion Panel Scribed to Metal |

2 Years |

No effect when rated using ASTM D-714. |

|||

| Distilled Water Immersion |

AWWA C-550 @ 150 °F |

Per AWWA C-550 |

Passed | ||

| Salt Fog (Scribed Panel) |

ASTM B-117 |

1 Year |

No effect when rated using ASTM D-714. |

||

| Impact Resistance |

ASTM 2794 |

Passed – 60 in./lbs. | |||

| Approval for contact with Potable water 4†and larger piping |

NSF 61 |

Approved | |||

| Undercutting Resistance: Alternate Wet/Dry Immersion |

(5% NaCl, flowing, aerated, 120 °F, Wet 1 hour followed by Dry 1 hour- 12 Cycles daily) |

1 Year |

No undercutting at exposed edges. | ||

| Weathering Exposure |

Coupons with cut edges exposed to ambient weathering conditions in Birmingham, AL |

1 Year |

Passed No undercutting at exposed edges. |

||

| Abrasion Resistance |

EN 598 |

One Million Cycles |

Less than 3 mils loss | ||

| Cathodic Disbondment |

ASTM G-95 (Attached Cell Method) |

Less than 2 mm disbondment | |||

LIMITATIONS:

The maximum continuous operating temperature for Ceramapure PL90 Ceramic Epoxy lined ductile iron pipe is 120 °F in immersion. Surges up to 150 °F may be allowed if the 150 °F is not the norm but is infrequent. Not recommended for dry heat above 200 °F (93 °C).

APPLICATION:

Certified Application is required. Please consult your Ductile Iron Pipe or Fittings manufacturer when ordering pipe or fittings lined with Ceramapure PL90 Ceramic Epoxy.

TOUCH-UP AND REPAIR:

CeramapureTM PL90 Ceramic Epoxy must be touched up or repaired using the published CeramapureTM PL90 repair procedure. CeramapureTM PL90 Ceramic Epoxy does not require scarifying of the surface prior to being recoated with itself if recoated within 30 days.

DRY FILM THICKNESS:

40 mils nominal for water or sewer service

Refer to Ceramapure PL90 specifications for water or sewer service.